SCF team has strong R&D capability with 25 engineers for products, mold design, formulation technology, aimed at petrochemical, hydraulic, pneumatic, pump and other directions. The company’s R&D department has cooperated with many universities like SCUT, GDUT and SIT to conduct lots of R&D projects. Meanwhile, SCF has hired professors from USA, Europe, and China as our long-term technical consultants to provide long-term technical guidance.

Material

After receiving information on the physical and chemical properties such as temperature, hardness, pressure, etc., we will apply our expertise and recommend the best solution to our clients. We can also develop new material to fit our customers’ specific needs.

Rubber: NBR, HNBR, FKM, FFKM, EPDM, AFLAS etc.

Plastic: PTFE, PEEK, PCTFE, UPE, PI, PA etc.

Polyurethane: High temp PU, Low temp PU, FDA approved PU etc.

Testing

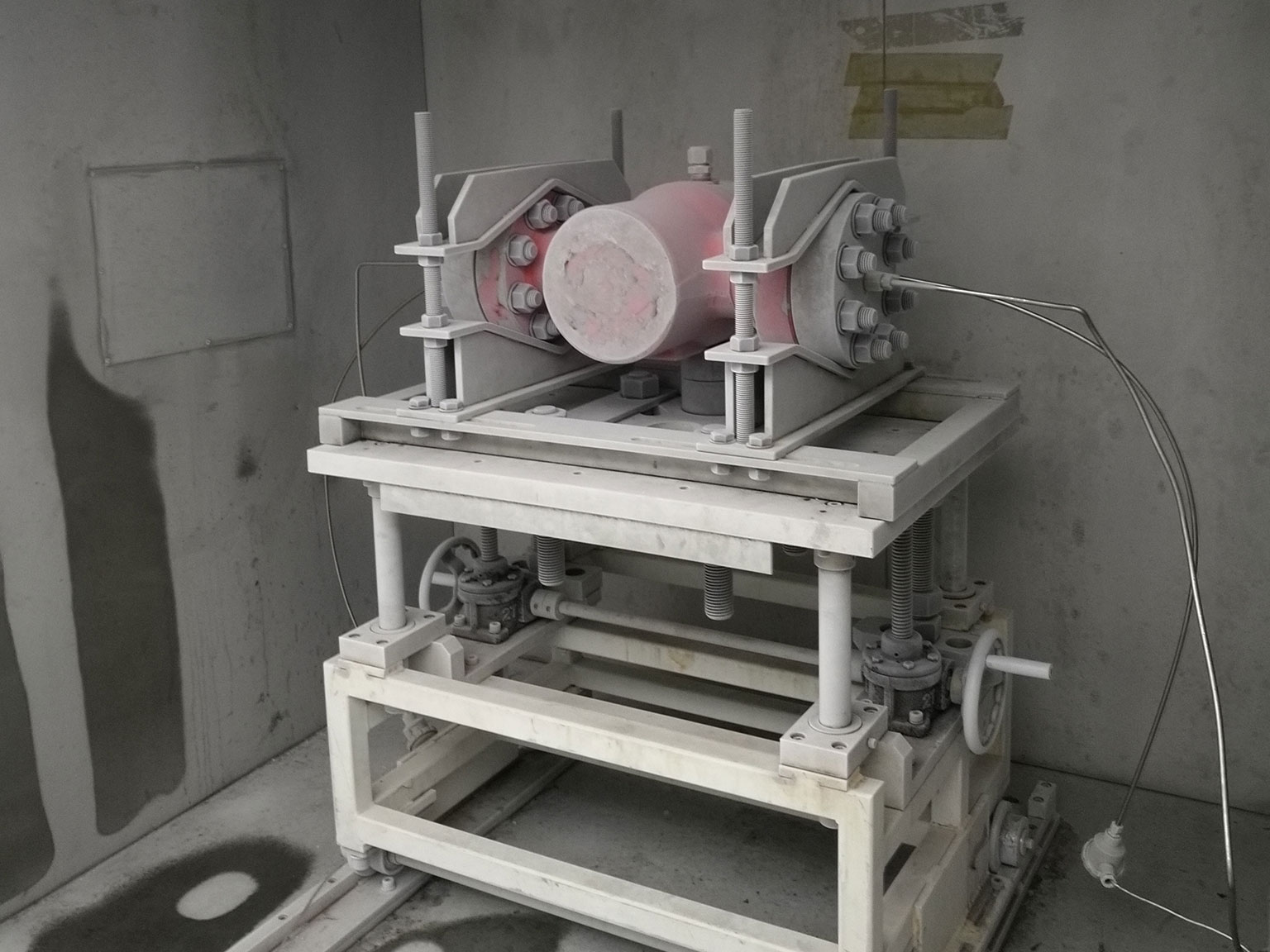

SCF has its own testing lab, as well as a wide range of testing equipment and simulation platforms. We can utilize our resources to test and gather accurate data on any sealing material and its properties. These data has assisted us in many of our material development and sealing designs.

API 6A Annex F PR2 Testing, Cryogenic (-196℃) Testing, Materials Performance Testing